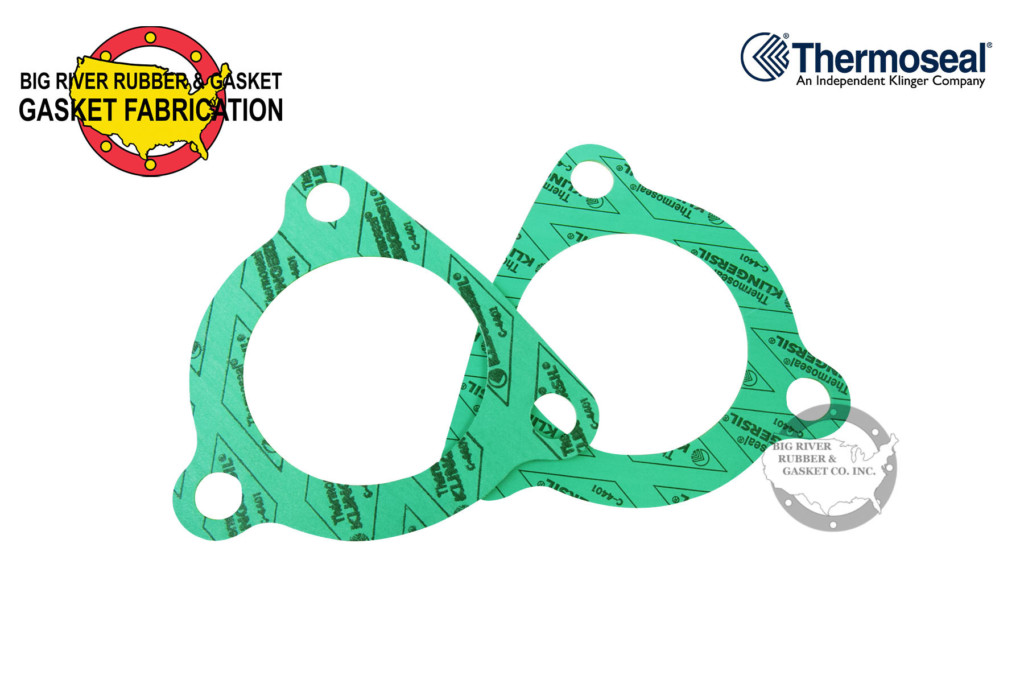

Thermoseal Klingersil Gasket C-4401

C-4401 Safety Data SheetCreep Relaxation ASTM F38B (1/32") | 20% |

Sealability ASTM F37A (1/32") | < 0.25 ml/hr |

Gas Permeability DIN 3535/6 | < 0.5 ml/min |

Compressibility ASTM F36J | 7% |

RecoveryASTM F36J | 50% minimum |

Klinger Hot Compression Test Thickness Decrease 73°F (23°C) Thickness Decrease 572°F (300°C) | 10.5% initial 17% additional |

Weight Increase ASTM F146 after immersion in Fuel B 5h/73°F (23°C) | 10% maximum |

Thickness Increase ASTM F146 after immersion in ASTM Oil 1, 5h/300°F (149°C) ASTM Oil IRM903, 5h/300°F (149°C) ASTM Fuel A, 5h/73°F (23°C) ASTM Fuel B, 5h/73°F (23°C) | 0-5% 0-5% 0-5% 0-7% |

Dielectric Strength ASTM D149-95a | 14 kV/mm |

ASTM F104 Line Call Out | F712121B3E12K6M5 |

Leachable Chloride Content FSA Method (Typical) | 100 ppm |

Density ASTM F1315 | 112 lb/ft³ (1.8 g/cc) |

Color(Top/Bottom) | Green |

This is a Big River Rubber & Gasket custom fabrication, made to one of our customers specifications.

We double check all shipments to make sure you receive the correct material.

If you call or email an order, we will fabricate your custom items to your specs and ship promptly.

This product is also found under: